ShaftAlign Touch is a combination of software and hardware innovations enabling maintenance teams to address a wide variety of alignment challenges that basic laser alignment systems cannot handle.

It also delivers premium Adaptive Alignment capabilities that, until now, were not available in an entry-level system.

Two innovations – single-laser technology and Active Situational Intelligence – differentiate ShaftAlign Touch from the competition.

Together, they deliver the “magic” that enables Prüftechnik alignment products to automatically adapt – in real-time, as alignment jobs are finished – to the asset, the situation, and the user’s experience level.SHAFTALIGN Touch | Laser Shaft Alignment | PRUFTECHNIK

ROTALIGN touch is the first laser shaft alignment tool fully designed to meet the requirements of industrial IoT with RFID, #wifi, and cloud data transfer.

The single-laser technology enables unrivaled precision, even in the harshest conditions and on highly demanding jobs. ROTALIGN touch was designed by some of the world’s leading #alignment experts to solve problems in the easiest way possible. The intuitively guided user interface can be operated by almost anyone – users just need to follow the three steps for any laser shaft alignment procedure: dimension, measure, and result.

This device is made for maximum #durability in extreme working conditions. It is IP65 waterproof and dust-proof, dirt, scratch, and temperature resistant. It is also fully shock and impact tested. ROTALIGN touch | advanced laser shaft alignment system | PRUFTECHNIK

The VIBXPERT II from PRUFTECHNIK is the mobile power package for fast and reliable recording and analysis of #machine condition data. After a very short measuring time, the current machine status data is shown on the color display. The #maintenance expert can analyze the data onsite. From the recorded machine condition data, all values can be read from the various characteristic value modes that are important for an exact #machinecondition analysis.

The device is used directly onsite at the machine, from the machine hall to the diesel generator of an oil tanker or from a bucket excavator to a #hydroelectric turbine. The robust design enables both fast and complex interventions. Whether in clinically clean systems, or harsh #industrialenvironments. VIBXPERT II sets the standard in mobile machines and plants #conditionmonitoring. VIBXPERT II | Vibration analysis system & balancing tool | PRUFTECHNIK

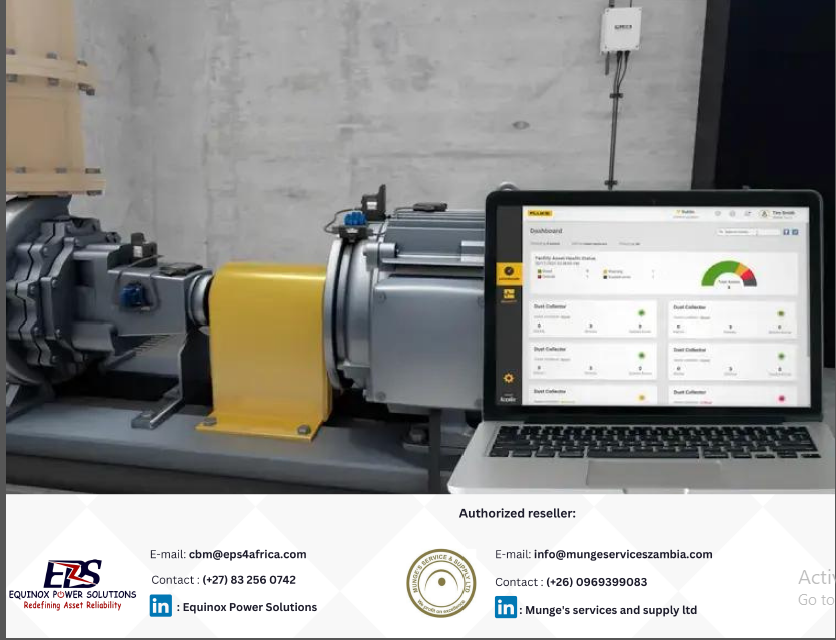

The Fluke 3562 Screening Vibration Sensor system is a complete solution empowering maintenance leaders and teams with reliable screening data at their fingertips.

A solution consisting of hardware, software, and service — the Fluke 3562 system provides vibration monitoring for a vast array of machines and machine types, not just the most critical few.

This technologically advanced sensor, which features battery-free operation and long-range radio sensor-to-gateway connection, combines with cloud-based software and notifications, to make the system the ideal always-on vibration screening solution for semi-critical and important machines.Fluke 3562 Screening Vibration Sensor | Condition Monitoring Sensor (pruftechnik.com)